Search Product

Structure Search

Search

Advantage Products

Location: Industrial Info

CAS:312619-41-3| Application of Iron(III) p-toluene sulfonate hexahydrate in Capacitors

Product Name:Iron(III) p-toluene sulfonate hexahydrate

CAS:312619-41-3

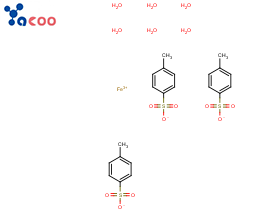

Molecular Formula:C21H21FeO9S3

Article No.:D0232

Structural Formula:

Product Introduction

Iron p-toluenesulfonate is a common organic iron complex with important application value in electrochemistry.

Application of Iron(III) p-toluene Sulfonate Hexahydrate

A capacitor is a device that can store charges and is one of the most fundamental and important components in electronic devices. According to the type of dielectric, capacitors can be divided into three categories: inorganic dielectric capacitors, organic dielectric capacitors, and electrolytic capacitors. Electrolytic capacitors have outstanding performance characteristics such as large capacitance per unit volume, large rated capacity, and low price.

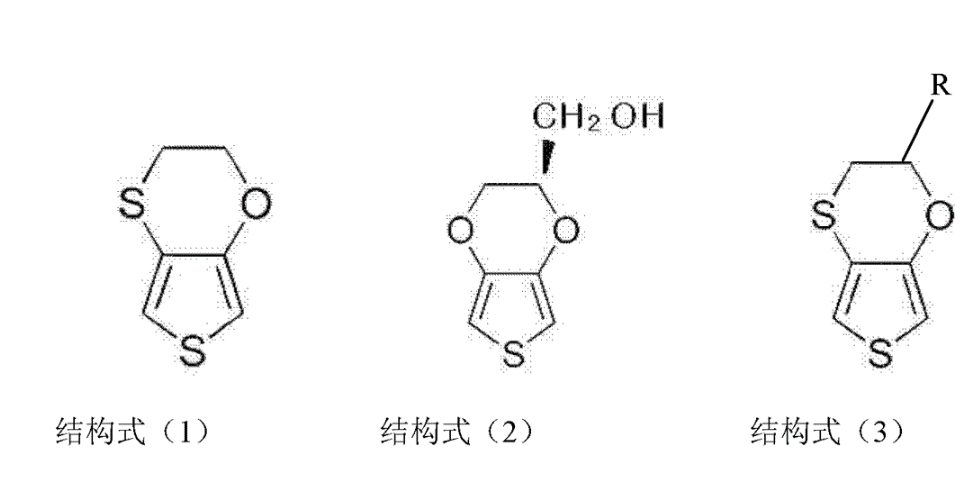

According to the anode of electrolytic capacitors, they can be divided into aluminum electrolytic capacitors, tantalum electrolytic capacitors, and niobium electrolytic capacitors. The traditional view was that tantalum capacitors had better performance than aluminum capacitors. At present, the key to determining the performance of electrolytic capacitors is not the anode, but the electrolyte, that is, the cathode. Compared to traditional aluminum electrolytic capacitors and organic semiconductor capacitors, aluminum solid-state conductive polymer capacitors use conductive polymers for conduction, have high conductivity and stability at high temperatures, low equivalent series resistance, and can withstand large filtering currents. Its conductivity is 1000 times that of traditional aluminum electrolytic capacitors. The performance of aluminum solid conductive polymer capacitors is influenced by the performance of the conductive polymer materials used. It is imperative to enhance the low leakage treatment ability and enhance the breakdown voltage of aluminum solid conductive polymer capacitors, and find a better conductive polymer material. Therefore, the CN102276805B patent provides a conductive polymer material, its production method, and a capacitor including it. The specific raw materials for the capacitor are: 40g of the first monomer with structural formula (1), 5g of the second monomer with structural formula (2), 55g of the third monomer with structural formula (3) (R is ethyl), and 1000g of iron p-methylbenzenesulfonate.

Prepare a mixed solution of the first monomer, second monomer, third monomer, and volatile solvent into a 60% concentration of monomers. Prepare a 40% concentration of oxidant solution of iron p-methylbenzenesulfonate and volatile solvent. Mix the mixed solution of monomers and oxidant solution evenly, and react for 45 minutes at 180 ℃ to obtain conductive polymer materials; Apply the conductive polymer material to produce aluminum solid conductive polymer capacitors. The volatile solvent is a methanol ethanol mixture, with a methanol content of 60%.

The present invention neutralizes excessive acid deposition in monomer solutions based on the principle of acid-base neutralization, inhibits the occurrence of acid catalyzed side reactions, and greatly improves the conductivity of conductive polymers.

References

CN102820138B A method for preparing high conductivity polymer electrolytic capacitors through in-situ oxidation polymerization.