Search Product

Structure Search

Search

Advantage Products

Location: Industrial Info

CAS:79803-73-9| The Application of MOPSO-Na in Coating

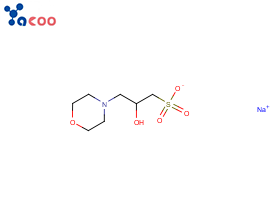

Product Name:MOPSO-Na

CAS:79803-73-9

Molecular Formula:C7H14NNaO5S

Article No.:M0004

Structural Formula:

Product Introduction

MOPSO-Na is a biological buffering reagent with an effective pH range of 6.2-7.6, which can be used as a buffering component, such as polyester resins, coatings, and IVD kits.

Application of MOPSO-Na

Nano carbon black has excellent coloring, weather resistance, and chemical stability, and is one of the important coloring agents with abundant sources and low prices. Nano carbon black is widely used in rubber, plastics, ink, and coatings. In many technical fields, it is necessary to apply coatings to achieve anti-corrosion, anti-oxidation, and aesthetic effects. For coatings used in humid environments, the coatings themselves need to have good anti mold properties. The anti mold performance of existing coatings is mainly achieved by adding anti mold agents to suppress the growth of microorganisms with their toxicity. The amount of anti mold agents added is generally between 1% and 2%. However, the method of adding anti mold agents inevitably affects the physical properties of the coating, and the anti mold agents form new potential sources of pollution. At the same time, anti mold coatings may cause allergic reactions in some areas that come into contact with the human body, affecting human health. So, currently, some anti mold technologies have turned to using photocatalysts for anti mold and sterilization to avoid adding additional anti mold agents. The CN114989657A patent has developed a method for preparing modified carbon black for anti mold coatings. The specific preparation method is as follows:

(1) Dissolve a mixed powder of zinc chloride and calcium chloride with a mass ratio of 10:1 in 80% ethanol to prepare a 5% zinc chloride solution.

(2) Disperse nano carbon black with a particle size of 20nm in water with a mass ratio of 5 times. After dispersion, introduce ozone at a gas-liquid ratio of 0.3L/L, and then raise the temperature to 70 ℃ to prepare a nano carbon black slurry.

(3) Add the zinc chloride solution to the nano carbon black slurry in a volume ratio of 1:8, and then add 5% of the total volume of the coating solution. After dispersion is complete, perform vacuum distillation to obtain modified carbon black.

The preparation process of the film coating solution is as follows: a mixed powder of chitosan and 3- (N-morpholine) -2-hydroxypropanesulfonate with a mass ratio of 4:1 is added to a saturated CO2 aqueous solution and stirred until completely dissolved to obtain the film coating solution.

This patent attaches a ZnO film layer to the surface of nano carbon black, giving it a photocatalytic effect. When added to coatings, it has anti mold and antibacterial effects; Introducing ozone can effectively increase the active sites of nano carbon black, resulting in a better photocatalytic sterilization effect of the ZnO film layer attached to its surface; By adding calcium chloride and coating solution in the modification process, the photo dissolution of ZnO can be effectively suppressed, the anti mold effect of modified carbon black can be improved, and the shelf life of modified carbon black can be extended.

References

CN114989657A Preparation method of modified carbon black for anti mold coating.