Search Product

Structure Search

Search

Advantage Products

Location: Thematic focus

CAS:110-26-9|Application of N,N'-Methylenebisacrylamide in Construction

Product Name/English Name:N,N'-Methylenediacrylamide

CAS:110-26-9

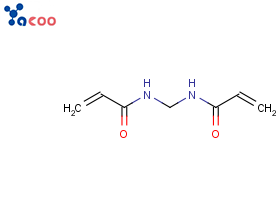

Molecular Formula:C7H10N2O2

Article No.:J0008

Structural Formula:

Product Introduction

N,N'-Methylenediacrylamide is a widely used crosslinking agent with stable quality, high purity, and good performance. It belongs to the thickening agent and adhesive of acrylamide. It is used in Textile manufacturing to produce thickening agent and adhesive, in oil exploitation to produce plugging agent. It is also widely used in various fields such as leather chemicals and printing.

Application of N,N'-Methylenediacrylamide

Ultra high performance concrete is a cementitious material based on tightly packed aggregates and cementitious materials, low water cement ratio, and steel fiber reinforcement. The impact and wear resistance of ultra-high performance concrete is significantly better than that of ordinary steel fiber concrete, and it is suitable for engineering such as water conservancy engineering. Compared with ordinary concrete, although it has made significant progress in mechanical properties and durability, shrinkage and cracking still exist during pouring and curing, greatly restricting the development and application of ultra-high performance concrete. Therefore, the CN116199481A patent develops an ultra-high performance concrete with low shrinkage and its preparation method. The specific preparation steps are as follows:

(1) Add basalt fibers to a mixed solution of H2SO4 and H2O2, and activate at 100-120℃ for 1-2 hours to obtain activated basalt fibers;

(2) Immerse the activated basalt fibers in a solution of vinyl silane coupling agent, stir at room temperature for 60-120 minutes, then remove the basalt fibers and cure at 50-60℃ for 6-12 hours to obtain vinyl silane coupling agent modified basalt fibers;

(3) Add vinyl silane coupling agent, modified basalt fiber, acrylic acid and acrylamide into deionized water, then add N, N-methylenebisacrylamide and Potassium persulfate, polymerize under nitrogen atmosphere, filter, wash and dry the reaction product after reaction, and obtain absorbent resin grafted basalt fiber;

(4) Disperse nano silica in toluene solvent, then add epoxy silicone oil to it, heat and stir for reaction. After the reaction is completed, filter, wash, and dry the reaction product to obtain modified nano silica;

(5) Mix and mix cement, fly ash, mineral powder, natural sand, water reducing agent, magnesium borate whisker, and modified nano silica according to the weight ratio to obtain the mixture. Then, add water to the mixture and stir it evenly. Then, add absorbent resin grafted basalt fiber and sepiolite fiber, mix them evenly, pour them into the mold, and pour them into shape to obtain ultra-high performance concrete with low shrinkage.

Compared with the existing technology, the present patent uses vinyl silane coupling agent to graft basalt fiber, and then graft the absorbent resin onto the surface of basalt fiber through the Addition reaction of carbon carbon double bond, which is conducive to good compatibility between fiber and concrete, and improves the dispersion effect of absorbent resin in concrete. The absorbent resin has a good three-dimensional network structure, and free water is fixed inside the resin through swelling, In a dry environment, water can be slowly released. By adding absorbent resin to concrete, it can not only offset the chemical shrinkage of the concrete, but also effectively reduce the self shrinkage of the concrete, suppress early shrinkage cracking, and thereby improve the strength of the concrete.

References

CN116199481A A low shrinkage ultra-high performance concrete and its preparation method.