Search Product

Structure Search

Search

Advantage Products

Location: Thematic focus

CAS:110-26-9|Application of N,N'-Methylenebisacrylamide in Polyethylene Foam

Product Name/English Name:N,N'-Methylenediacrylamide

CAS:110-26-9

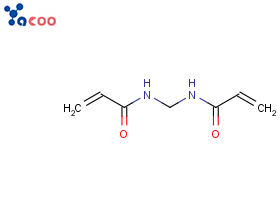

Molecular Formula:C7H10N2O2

Article No.:J0008

Structural Formula:

Product Introduction

N,N'-Methylenediacrylamide is a widely used crosslinking agent with stable quality, high purity, and good performance. It belongs to the thickening agent and adhesive of acrylamide. It is used in Textile manufacturing to produce thickening agent and adhesive, in oil exploitation to produce plugging agent. It is also widely used in various fields such as leather chemicals and printing.

Application of N,N'-Methylenediacrylamide

Polyethylene foam is a widely used cushioning material. Polyethylene foam is characterized by low density, stable chemical performance, resistance to corrosion, tenacity, flexibility, friction resistance, good processing performance, easy molding and low price. Polyethylene foam is widely used for buffer packaging of precision instruments, household appliances, glass and ceramic products, handicrafts, valuables, etc., and can also be made into thermal insulation containers for frozen food and hot food. The strength of traditional polyethylene foam is low, and it cannot be completely degraded. Therefore, CN116120652A patent develops a polyethylene foam material and its preparation method. The polyethylene foam specifically contains 65% polyethylene, 10% nano shell powder composite, 3.9% Bamboo textile, 1.3% Alginic acid extract, 2.7%N,N'- methylenebisacrylamide, 5.4% tert amyl peroxide (2-ethylhexyl) carbonate, 2.7% ammonia remover, 7.5% azodicarbonamide, 0.5% Fatty alcohol polyoxyethylene ether sodium sulfate, 0.3% tri Allyl group isocyanurate, Calcium stearate 0.7%.The specific preparation steps are as follows:

(1) Melting polyethylene, adding nano shell compound, Bamboo textile, Alginic acid extract, granulating, and preparing modified polyethylene particles;

(2) The modified polyethylene particles prepared in step (1) are mixed with N, N '- methylenebisacrylamide, tert amyl peroxide (2-ethylhexyl) carbonate, ammonia remover, azodicarbonamide, Fatty alcohol polyoxyethylene ether sodium sulfate, tri Allyl group isocyanurate, and Calcium stearate for homogenization. Under the flow and purging of nitrogen, vacuum heating and positive pressure heating are used for cycling and alternating heating for foaming to obtain dry composites;

(3) The high strength and degradable polyethylene foam material is obtained by solidification molding in the mold.

Compared with the existing technology, the friability and breakage rate of the product will be reduced and the strength of the product will be significantly improved by modifying polyethylene with nano shell complex and adding N, N '- methylenebisacrylamide and tert amyl peroxide (2-ethylhexyl) carbonate in a specific proportion. By adding specific proportion of Alginic acid extract and Bamboo textile, the degradability of the product is significantly improved.

References

CN116120652A Polyethylene foam material and its preparation method.