Search Product

Structure Search

Search

Advantage Products

Location: Thematic focus

CAS:935-79-5| The Application of THPA in CTP Thermosensitive Plate

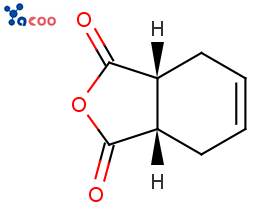

Product Name/English Name:cis-1,2,3,6-Tetrahydrophthalic anhydride

English abbreviation:THPA

CAS:935-79-5

Molecular Formula: C8H8O3

Article No.:S1112

Structural Formula:

Product Introduction

THPA is an important chemical product, mainly used as a curing agent for epoxy resins, a modifier for unsaturated polyester resins and alkyd resins, and an important intermediate in the synthesis of pesticides and pharmaceuticals. In addition, THPA can also be used in thermosensitive sheets.

Application of THPA

The printing process is achieved by applying the principle of ink and water balance. During the printing process, there is a fountain process. In order to reduce the indicated tension of the fountain solution, a certain amount of organic solvent is added to the fountain solution. In the prior art, acrylamide, acrylamide Sulfonamide, N-nenenebc imide group or N-vinylamide polymer are usually added to the thermosensitive layer formula of Planographic printing plate to improve the solvent resistance of Planographic printing plate, and the solvent resistance of Planographic printing plate can also be improved by connecting amide and Imide structural units to the phenolic resin. However, although the solvent resistance of the printing plate has been improved, the addition of the aforementioned polymers can cause poor alkaline resistance, softer hardness, and reduced development tolerance of the unexposed part of the printing plate precursor. In order to solve the problems existing in the prior art, the CN104742492B patent provides a dual coating positive image thermal sensitive CTP plate. The positive thermosensitive CTP board will be coated with a resin layer and a thermosensitive layer on the support body of the hydrophilic surface.

The resin layer includes 10 parts by weight of N, N-di N-Methylformamide, 10 parts by weight of butyl acetate, 65 parts by weight of ethyl fiber solvent, 10 parts by weight of UV-1 resin, 4 parts by weight of o-or p-toluenesulfonamide formaldehyde resin, 0.5 parts by weight of tetrahydrophthalic anhydride, and 0.5 parts by weight of Methyl violet.

Adding o-or p-toluenesulfonamide formaldehyde resin to the positive thermal photosensitive composition component can improve the solvent resistance of the thermal sensitive coating, because it contains Sulfonamide groups and has good solvent resistance compared with phenolic resin and general acrylate resin. When printing with alcohol fountain solution and UV ink, it can obtain satisfactory print quality and printing process. At the same time, this resin is a bonding accelerator, It can enhance its adhesion to the plate and also enhance its printing resistance.

References

CN104742492B A dual coating positive image thermal sensitive CTP plate.