Search Product

Structure Search

Search

Advantage Products

Location: Thematic focus

CAS:126213-50-1| Application of EDOT in Solid Electrolytic Capacitors

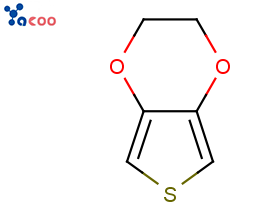

Product Name:2,3-dihydrothieno[3,4-b][1,4]dioxine

English abbreviation:EDOT

CAS:126213-50-1

Molecular Formula:C6H6O2S

Article No.: Y0038

Structural Formula:

Product Introduction

EDOT is mainly used for synthesizing conductive polymer PEDOT, as well as for synthesizing conjugated polymers and copolymers. It can also be used as a reducing agent in the synthesis of gold nanoparticles and as a raw material in palladium catalyzed single arylation and double arylation reactions. In addition, EDOT can also be used for solid electrolytic capacitors.

Application of EDOT

In recent years, with the digitization of electronic instruments, there has been a gradual demand to reduce the impedance of the capacitors used in the high-frequency region. In order to meet the requirements, anodes composed of metal porous bodies such as aluminum and tantalum (Ta) with valve action, dielectric oxide films composed of valve action metal oxide films, and cathodes formed by conductive polymer layers, carbon layers, and silver layers as solid electrolytes were gradually used to obtain the anode. As the conductive polymer layer of the solid electrolyte of the functional capacitor, pyrrole, thiophene, aniline, etc. are used as monomers. The conductive polymers include polypyrrole, polythiophene, polyacetylene, polyphenylene, 1,2-ethylene, polyaniline, acetaldehyde, poly 1,2-ethylene thiophene, and their copolymers. Conductive polymers can be prepared through chemical oxidation polymerization and electrolytic polymerization methods. The electrolytic polymerization method is difficult to prepare in large quantities, and the chemical oxidation polymerization method mostly produces insoluble solid powders. To solve this problem, the CN101486839B patent provides a conductive polymer composition, a solid electrolyte, and a solid electrolytic capacitor using the solid electrolyte. The specific preparation steps for conductive polymer compositions and solid electrolytic capacitors are as follows:

1. Dissolve 5g of 3,4-ethylenedioxythiophene (CAS: 126213-50-1), 50g of 30wt% polystyrene sulfonic acid aqueous solution, 10g of sodium persulfate, and 1g of iron sulfate in 1000ml of water, and stir for 18 hours.

2. Remove residual ions from the solution using ion exchange resin to obtain a dark blue 1.5wt% polystyrene sulfonic acid poly (3,4-ethylenedioxy) thiophene aqueous solution.

3. Obtain 5g of 1.5wt% polystyrene sulfonic acid poly (3,4-ethylenedioxy) thiophene aqueous solution, 0.05g of 4-nitrophenol mixed and stirred, and dry in a 120℃oven to obtain a conductive coating.

The present invention patent provides a conductive polymer composition capable of obtaining a coating film, which has the ability to reduce electrical resistivity and maintain low electrical resistivity even in high-temperature environments.

References

CN101486839B Conductive polymer composition, solid electrolyte, and solid electrolytic capacitor using the solid electrolyte.